When it comes to the aviation industry, maintaining the highest standards of efficiency, safety, and compliance is essential. A key factor in achieving this is effective tool control and management.

An MRO (Maintenance, Repair, and Operations) tool control solution is more than just a utility—it’s the cornerstone of operational efficiency, safety, and compliance with industry regulations. This software enables real-time tracking of tools, fostering a safer work environment and streamlining maintenance repair operations.

In the fast-paced world of aircraft maintenance, the lack of a robust tool management system can result in bottlenecks, higher costs, and safety risks. Misplaced or unavailable tools can cause delays, while defective or uncalibrated tools may compromise safety.

An effective MRO tool control solution addresses these challenges by offering a comprehensive framework for tool tracking, calibration maintenance, and ensuring tools are in good working condition.

In this post, we’ll walk you through the 5 essential things to look for when choosing the right MRO tool tracking solution for your operations.

1. Comprehensive Tool Tracking Capabilities

When evaluating an MRO tool control solution, one of the most critical features to look for is comprehensive tool tracking capabilities. This ensures that you can monitor and manage your tools efficiently, reducing the risk of tool loss, misplacement, and downtime.

Real-Time Location System (RTLS)

A robust MRO tool control solution should incorporate a Real-Time Location System (RTLS) to provide continuous monitoring of tool usage and location. This system allows for the precise tracking of tools as they move within the maintenance facility. For instance, using RFID technology, tools can be tagged and tracked in real-time, enabling maintenance teams to quickly locate the tools they need, thereby reducing delays and increasing operational efficiency.

Integration with Barcodes and RFID

Effective tool tracking also involves the integration of various identification technologies, such as barcodes and RFID tags. RFID technology, in particular, offers significant advantages over traditional barcode systems. RFID tags can be attached to or embedded in tools, allowing for fast and accurate identification even when tools are covered or inside containers. This eliminates the need for direct line-of-sight scanning, which is a limitation of barcode systems.

Additionally, RFID enables bulk scanning, which can significantly speed up the tool tracking process. Moreover, the combination of RFID and barcode scanning can be integrated into tool management software to provide a comprehensive view of tool inventory, movement, and maintenance status. This integration ensures that all tools are accounted for, properly maintained, and calibrated, adhering to industry safety standards and regulations.

2. Scalability and Customization

When selecting an MRO tool control solution, it is important to consider its ability to scale and adapt to the evolving needs of your organization. Here are some key aspects to focus on :

Flexible to Business Growth

An ideal MRO tool control solution should be designed to grow with your business. This means the software should offer flexible architecture and modular scalability. Cloud-based hosting is particularly beneficial as it eliminates the need for infrastructure upgrades and provides global accessibility, allowing your operations to scale quickly and efficiently.

For instance, cloud-based platforms enable you to add new features and functionalities as your fleet expands or as regulatory requirements change. This modular approach ensures that the software can adapt to different regional regulations without disrupting your operations. As a result, managing your tool inventory and maintenance processes across various locations becomes significantly easier.

Customizable Features

Customization is another vital aspect of an effective MRO tool control solution. The software should be highly customizable to meet the specific needs of your organization. This includes the ability to configure custom workflows, fields, and dashboards that align with your unique operational requirements.

Customizable features allow you to tailor the system to your specific tool management processes, whether it involves tracking calibration dates, monitoring tool movement, or generating reports for reordering broken tools. This flexibility ensures that the software integrates seamlessly with your existing workflows and systems, such as ERP platforms, to prevent data silos and streamline administrative tasks.

Moreover, customizable solutions enable you to address specific industry challenges and best practices, ensuring that the tool control system is not just a generic solution but a tailored fit for your aviation maintenance operations. This level of customization can significantly enhance operational efficiency, reduce training time, and improve overall user satisfaction.

3. Advanced Reporting and Analytics

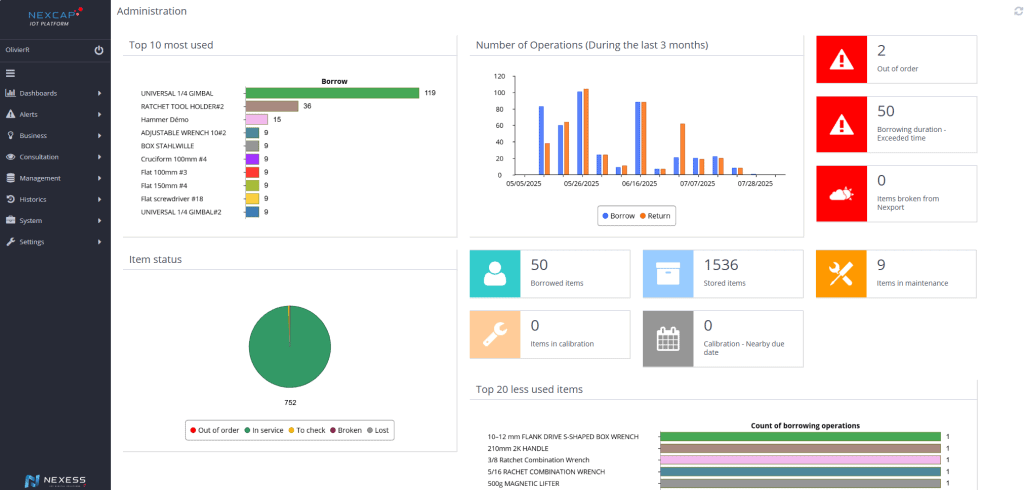

NexCap customizable reports and dashboards regarding tool utilization

Advanced reporting and analytics are essential components of an effective MRO tool control solution. They empower you to make data-driven decisions that enhance operational efficiency, reduce costs, and improve overall profitability.

Detailed Usage Reports

Detailed usage reports are essential for understanding how tools are being utilized within your maintenance operations. These reports provide a clear breakdown of tool usage patterns, including which tools are used most frequently, by whom, and for what specific tasks. This level of detail offers several key benefits:

-

Work Order Profitability: By analyzing the costs associated with each work order, including labor and material expenses, you can identify which jobs are most profitable and adjust your pricing strategies accordingly. For instance, a work order profitability report can help you understand the revenue versus costs for each job, enabling you to focus on high-margin services.

-

Inventory Management: Detailed usage reports also help in optimizing inventory levels. By tracking the real-time movement of tools and parts, you can avoid stockouts or overstocking, ensuring that critical tools are always available when needed. This data is vital for making informed decisions about inventory investment and reducing carrying costs.

-

Supplier Management: These reports can highlight trends in purchasing, allowing you to control rogue spend by identifying opportunities to reduce spot buys and route purchases through your preferred supplier network. This helps in rationalizing your supplier base and improving spend analysis for efficient supply chain operations.

Asset Performance Analytics

Asset performance analytics take reporting to the next level by providing insights into the performance and health of your tools and equipment. These insights include:

-

Trend Analysis: By analyzing historical data on tool failures and maintenance activities, you can identify trends that were previously not visible. This allows maintenance teams to anticipate and prevent future failures, reducing downtime and improving overall equipment reliability.

-

Supplier and Part Performance: Advanced analytics can cross-reference MRO parts with suppliers, ensuring correct UNSPSC codes and other spend codes are used. This helps in evaluating the performance of different suppliers and identifying alternative sources, which can mitigate risks and improve supply chain efficiency.

-

Data-Driven Decision Making: Asset performance analytics enable you to translate data into actionable business outcomes. For example, understanding the costs and lead times of critical spare parts can help in making strategic decisions about inventory levels and procurement strategies. This ensures that maintenance operations are optimized and that critical parts are always available when needed.

By leveraging these advanced reporting and analytics capabilities, you can gain a deeper understanding of your MRO operations, make more informed decisions, and drive significant improvements in efficiency, cost management, and overall profitability.

4. Enhanced Security Features

Ensuring the security and integrity of your tool inventory is a critical aspect of an effective MRO tool control solution. Here are some key security features to look for :

User Authentication

User authentication is essential to ensure that only authorized personnel have access to tools and sensitive data. A robust MRO tool control solution should include advanced access control mechanisms such as multi-factor authentication, role-based access, and secure login protocols. For instance, access control can be integrated with RFID reader checkpoints, where only authorized personnel can access certain tools or areas. This ensures that tools are not misused or taken by unauthorized individuals, maintaining a high level of security and accountability within the maintenance facility.

Additionally, user authentication can be tied to specific roles and permissions, ensuring that technicians and maintenance staff only have access to the tools and data necessary for their tasks. This not only enhances security but also helps in maintaining compliance with industry regulations such as GDPR and FAA/EASA guidelines

NexCap RFID cabinets are equipped with RFID badge readers to control access and automatically log all tool check-ins and check-outs.

Theft and Misplacement Alerts

Theft and misplacement of tools can be a significant issue in MRO operations, leading to downtime, increased costs, and potential safety risks. An advanced MRO tool control solution should include features that alert users to any unauthorized removal or misplacement of tools. RFID technology plays a key role here, as it allows for real-time monitoring of tool locations. Unattended readers can issue alerts if tagged equipment is removed from authorized areas or left unattended. This immediate notification helps in quickly identifying and recovering missing tools, preventing theft and reducing the likelihood of Foreign Object Damage (FOD).

Moreover, automated check-in/check-out procedures can be set up to ensure that tools are properly accounted for at all times. This creates a transparent audit trail, which is essential for compliance and security checks. The system can also generate reports on tool movement and usage, helping to identify patterns or anomalies that might indicate theft or misplacement.

5. Seamless Integration with Existing Systems

When selecting an MRO tool control solution, ensuring it integrates seamlessly with your existing systems is essential for maintaining operational efficiency and minimizing disruptions. Here are some key aspects to consider :

Compatibility with ERP Systems

Integration with Enterprise Resource Planning (ERP) systems is essential for a cohesive and efficient MRO operation. An ideal MRO tool control solution should integrate smoothly with your ERP system, allowing for real-time data exchange and synchronization. For instance, integrating RFID tool tracking with ERP systems streamlines inventory management, improves data accuracy, and enhances accessibility.

This integration enables automated updates of tool inventory, usage, and maintenance records, ensuring all relevant data is consistent across systems. Moreover, this compatibility supports automating procurement processes, such as generating purchase orders for tools nearing the end of their lifecycle or requiring replacement. This automated workflow reduces manual errors and ensures the procurement process aligns with the actual needs of maintenance operations.

Support for Multiple Platform Integration

In addition to ERP systems, an MRO tool control solution should support integration with various other platforms and systems critical to your operations. This includes Maintenance, Repair, and Overhaul (MRO) software, Computerized Maintenance Management Systems (CMMS), and Warehouse Management Systems (WMS).

These integrations enable real-time visibility into tool usage, maintenance schedules, and inventory levels, ensuring all aspects of your MRO operations are well-coordinated and efficient.

Furthermore, the use of open APIs and modular architecture in these systems allows for easy integration with other specialized software, such as tool crib management and logistics management tools. This ensures the MRO tool control solution can adapt to the specific needs of your organization and integrate seamlessly with your existing technology infrastructure.

Conclusion

When selecting an MRO tool control solution, it is important to consider several key factors to ensure optimal efficiency, safety, and compliance in your aviation maintenance operations. Remember to look for comprehensive tool tracking capabilities, including real-time location systems and RFID integration, to minimize tool loss and misplacement.

Scalability and customization are essential to adapt to your growing business needs. Advanced reporting and analytics will help you make data-driven decisions, while enhanced security features will protect your tools and data. Finally, seamless integration with existing systems such as ERP and M&E systems is vital for streamlined operations.

By focusing on these critical aspects, you can significantly enhance operational efficiency, reduce costs, and foster a safer work environment. Don’t hesitate to explore solutions like RFID-based tool tracking and advanced MRO software to transform your maintenance operations. Take the first step today by requesting a demo or consulting with industry experts to find the perfect solution for your needs.

FAQ

Yes, investing in an automated tool control system is cost-effective for MRO operations. It reduces tool loss, minimizes downtime, improves inventory accuracy, and enhances compliance, leading to significant long-term savings and increased operational efficiency.

MRO (Maintenance, Repair, and Overhaul) software is a comprehensive solution designed to manage and optimize processes related to maintaining physical assets, such as aircraft or industrial equipment. Its features include:

-

Maintenance planning, scheduling, and execution

-

Inventory and parts management

-

Compliance and regulatory management

-

Predictive maintenance using data analytics to enhance operational efficiency, safety, and compliance

The primary purpose of tool control is to ensure that all tools are accounted for, reducing the risk of them being left in aircraft or work areas. This helps prevent safety risks, Foreign Object Damage (FOD), and maintenance errors. Additionally, tool control ensures tools are calibrated, maintained, and used efficiently, which enhances both safety and productivity.

To maintain aircraft tools effectively:

-

Follow rigorous calibration schedules and conduct regular inspections for wear and damage

-

Promptly repair or replace faulty tools

-

Ensure compliance with FAA and ICAO regulations

-

Maintain detailed records and provide training on proper tool use and care

Additionally, tools should be centralized, tracked, and returned to stores after use. Upon return, conduct serviceability checks to ensure they are in proper working condition.

Français

Français