In the highly regulated world of airline Maintenance, Repair, and Overhaul (MRO), keeping systems and data synchronized is essential for operational efficiency and compliance. Two key components—tool management software and MRO software—when integrated, can significantly improve performance and accuracy in maintenance operations. A data synchronization tool plays a pivotal role here, automating the alignment and real-time updates of data across systems to ensure consistency.

Consider a scenario where a technician needs access to the latest inventory of tools and equipment, but data discrepancies between the tool management system and MRO software cause delays, misallocations, or even safety risks. This highlights the critical need for synchronization.

By leveraging a robust synchronization tool, you can ensure accurate data across systems—covering tool tracking, inventory management, work orders, and maintenance records.

This article explores the benefits of integrating tool management software with MRO systems and provides strategies for achieving effective synchronization. Whether aiming to enhance efficiency or streamline data management, this guide offers actionable insights for informed decision-making.

Understanding the Need for Synchronization

The Role of Tool Management in MRO Operations

Tool management is a critical component of Maintenance, Repair, and Overhaul (MRO) operations in the aviation industry. Effective tool management ensures that the right tools are available, calibrated, and in good working condition, which is essential for maintaining the safety, efficiency, and regulatory compliance of aircraft maintenance activities. Tool management software plays a vital role in this process by facilitating tasks such as tool inventory management, tracking, calibration, and certification.

For instance, tool inventory management involves cataloging and tracking a diverse array of tools, which helps in conducting regular audits and inspections. This ensures that all tools are accounted for and that any discrepancies or missing tools are promptly addressed. Additionally, tool calibration and certification are essential to maintain the accuracy and reliability of precision tools, adhering to stringent aviation standards.

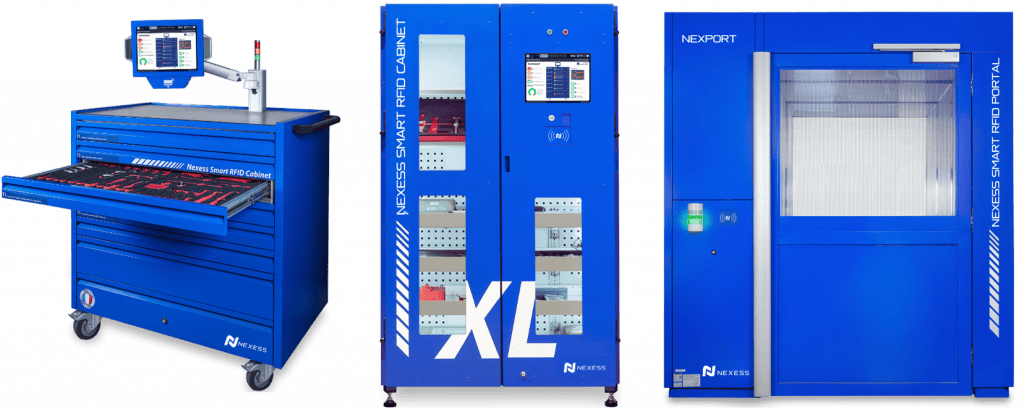

This is exactly what NexCap RFID product lineup are designeg for: auto-inventory of tools, automatic check in and check out, real-time traceability and alerts.

NexCap RFID Tool Management solutions ready to be connected to MRO softwares through API’s

Challenges in Unsynchronized Systems

Without synchronization between tool management software and MRO software, several challenges can arise that impact the efficiency and safety of maintenance operations. One of the primary issues is data inconsistency. When data is not synchronized in real time, it can lead to discrepancies in tool inventories, calibration records, and usage logs.

This can result in delays, as technicians may spend valuable time searching for tools or verifying their status, which can also lead to safety risks if the wrong or uncalibrated tools are used.

Another significant challenge is the increased risk of human error. Manual data entry and updates can be prone to mistakes, which can compromise the integrity of the maintenance process.

For example, if a tool’s calibration status is not updated in both systems, it could be used beyond its calibrated period, potentially leading to faulty repairs or safety hazards.

Furthermore, unsynchronized systems can hinder the ability to implement efficient tool control procedures. Controlled access to critical and specialized tools is essential to prevent unauthorized use and ensure security. However, without real-time synchronization, managing access and tracking tool usage becomes more complex, increasing the risk of errors and security breaches.

In summary, the lack of synchronization between tool management and MRO software can lead to operational inefficiencies, increased risks, and potential safety issues. Therefore, integrating these systems is not just beneficial but essential for maintaining high standards of safety, compliance, and operational efficiency in aircraft maintenance.

Benefits of Synchronizing Tool Management with MRO Software

Enhanced Operational Efficiency

Synchronizing tool management software with MRO software can significantly enhance operational efficiency in several ways. By automating data flows between these systems, manual input is reduced, and errors are minimized. This integration allows for seamless updates of work orders, inventory tracking, and maintenance schedules, ensuring that all departments have access to the most current information.

For instance, when a technician completes a maintenance task, the tool management system can automatically update the MRO software, reflecting the latest status of the tools and equipment used. This real-time synchronization enables faster turnaround times for aircraft maintenance, as technicians can quickly access the tools they need and complete tasks without unnecessary delays.

Additionally, predictive maintenance capabilities are enhanced when tool management and MRO software are synchronized. By analyzing data from both systems, maintenance teams can better forecast potential issues and prevent unexpected breakdowns. This proactive approach reduces downtime and ensures that maintenance activities are well-coordinated, optimizing the overall efficiency of the maintenance process.

Operator in MRO workshop with aircraft in the background

Improved Compliance and Safety

Synchronizing tool management with MRO software also significantly improves compliance and safety in aircraft maintenance. Ensuring that all tools are properly calibrated, certified, and tracked is essential for maintaining regulatory compliance. When these systems are integrated, the software can automatically generate and update audit trails, compliance documents, and maintenance records, reducing the risk of non-compliance and associated penalties.

This integration ensures that all maintenance activities meet global safety standards set by regulatory bodies such as the FAA and EASA, providing a robust framework for maintaining safety and compliance.

Moreover, synchronized systems help in maintaining accurate and up-to-date records of tool usage, calibration, and certification. This ensures that only approved and calibrated tools are used in maintenance activities, which is critical for preventing safety hazards and ensuring the reliability of aircraft repairs.

By having a unified system, airlines and MRO providers can be audit-ready at all times, with all necessary documentation readily available.

Optimized Inventory Management

The synchronization of tool management and MRO software leads to optimized inventory management, which is vital for efficient aircraft maintenance. With real-time visibility into tool inventories, maintenance teams can better manage stock levels, reducing the risk of shortages or overstocking.

Automated replenishment features can predict future tool needs based on historical data and usage patterns, ensuring that the necessary tools are always available when needed. This optimization minimizes manual intervention, reduces inventory costs, and ensures that maintenance activities are not delayed due to tool unavailability.

Furthermore, integrated systems enable better tracking and control of tools and equipment. This helps in preventing tool misplacement or loss, which can be costly and time-consuming to rectify.

By ensuring that all tools are accounted for and their status is updated in real time, airlines and MRO providers can maintain a more efficient and cost-effective inventory management process.

Strategies for Effective Synchronization

Integrating Software Platforms

To achieve effective synchronization between tool management software and MRO software, integrating these platforms is essential.

This integration involves connecting various software systems, such as Enterprise Resource Planning (ERP), Computerized Maintenance Management Systems (CMMS), and other business-related systems using APIs. An API (Application Programming Interface) is a set of rules and tools that allows different software systems to communicate and share data or functionality securely and efficiently.

By integrating these platforms using APIs, you can ensure seamless information sharing between departments, accurate tracking of tools and parts, and up-to-date maintenance schedules.

For instance, using advanced tooling inventory management software that integrates with MRO systems allows for real-time tracking, automated reordering, and comprehensive data analytics. This integration helps in managing a diverse range of tools, tracking their usage, and ensuring that all necessary data is synchronized across different systems.

Additionally, integrating data taxonomies and standard modifier dictionaries can enhance the consistency and quality of the data, making it easier to manage and analyze.

Automated Data Sharing and Updating

Automating data sharing and updating processes is a key strategy for effective synchronization. This can be achieved by embedding automated data scrubbing directly into Extract, Transform, Load (ETL) workflows.

This approach ensures that data is cleaned and validated in real-time as it moves between systems, preventing poor-quality data from entering critical systems like CMMS or ERP platforms.

Using machine learning algorithms can also help in detecting patterns and anomalies in large datasets, predicting missing values, and correcting errors. This automated process improves over time as it learns from new data, making it an essential tool in maintaining data quality and consistency. Moreover, cloud-based MRO software solutions can be configured for data validation systems, approval processes, and autonomously fetching missing information, ensuring that data remains accurate and up-to-date.

Training and Change Management

Implementing effective synchronization also requires thorough training and change management. Ensuring that staff is trained on the proper use, storage, and maintenance of tools and spare parts is essential. Standardizing procedures and enhancing employee training can minimize errors and improve efficiency.

It is essential to maintain an open line of communication with technicians and staff regarding tool performance, reliability, and usability to continuously improve tooling strategies.

Change management is equally important, as it involves managing the transition to new integrated systems smoothly. This includes aligning multiple stakeholders and cross-functional teams to ascertain the best possible processes, approval flows, and practices to be adopted during data entry. Regular audits and data governance frameworks should be established to monitor and enforce compliance with established standards, ensuring that the data quality is maintained over time.

Uses cases : connexion between nexcap and mro softwares

NexCap and AMOS (Swiss Aviation Software)

Swiss-AS is a highly experienced provider in the Maintenance, Repair & Overhaul (MRO) software market, solely focused on developing and supporting its flagship solution: AMOS. Rooted in Swiss values of quality, reliability, and safety, the company is part of one of the world’s largest airline groups and maintains strong financial stability.

For a european MRO customer, Nexess has connected NexCap Tool Management Software to AMOS using APIs to automatically log in real-time tool booking status (check in / check out), linked to work orders and job cards.

NexCap and Tracing Flight

TracingFlight is an all-in-one aviation software suite by Ixarys that streamlines airworthiness (CAMO), MRO operations, and document management for aircraft and helicopter operators. Trusted by professionals across the industry, it combines regulatory compliance, digital efficiency, and intuitive design to optimize fleet maintenance and safety.

Nexess has connected NexCap Tool Management Software to Tracing Flight using APIs to automatically log in real-time tool booking status to improve tool availabilities during maintenance tasks.

Conclusion

Synchronizing tool management software with airline MRO software is a critical step in enhancing operational efficiency, compliance, and safety within the aviation industry. By integrating these systems, airlines and MRO providers can streamline maintenance processes, reduce downtime, and improve decision-making through real-time data access.

Key benefits include enhanced operational efficiency, improved compliance and safety, and optimized inventory management. However, successful integration requires careful consideration of platform compatibility, data migration, and change management.

To reap these benefits, it is essential to select flexible and scalable software solutions, ensure accurate data migration, and provide comprehensive training to maintenance and IT teams. By leveraging advanced MRO software features such as predictive maintenance, automated work order management, and real-time inventory tracking, organizations can significantly improve their maintenance operations.

Take the first step today by evaluating your current systems and identifying areas for integration. With the right approach and tools, you can transform your maintenance operations, reduce costs, and enhance overall performance. Start your journey towards a more efficient, compliant, and safe maintenance environment.

FAQ

A synchronization tool is a software application designed to ensure data consistency and updates across different locations, devices, or systems. It helps maintain uniformity of data, enabling real-time access and automated updates. This is essential for improving productivity, collaboration, and data security.

Synchronization software is a digital solution that ensures data consistency and updates across multiple devices or systems. It automatically synchronizes files, data, or information in real time, eliminating duplication and errors. Commonly used in collaboration tools, backup systems, and file-sharing platforms, it keeps data up-to-date and synchronized.

Not using synchronization tools in maintenance operations can lead to data inconsistencies, delays, and safety risks. Without real-time synchronization, tool inventories, calibration records, and maintenance logs may become outdated or contradictory across systems. This increases the risk of using uncalibrated tools, missing critical compliance checks, or duplicating tasks. Moreover, lack of synchronization can slow down decision-making, disrupt workflow coordination, and compromise regulatory audit readiness.

Synchronization tools often include conflict resolution mechanisms to handle data duplicates or inconsistencies. When two systems have conflicting updates, the tool can apply predefined rules—such as prioritizing the most recent change or a trusted source—or flag the conflict for manual review. Advanced solutions may use version control, audit trails, or machine learning algorithms to detect anomalies and suggest resolutions. This ensures data integrity is maintained across all connected systems.

Français

Français