XL RFID Cabinet

Home > IoT products in industrial traceability > XL RFID Cabinet

NEXCAP® offering:

The XL self-inventorying smart cabinet ensures the detection and traceability of all types of industrial equipment, from hand tools requiring calibration to the smallest tool. This IoT solution, also known as second-generation UHF RFID smart cabinet, is based on high-performance RFID technology. The XL Cabinet provides a precise and accurate inventory of your tools. Each operation is tracked via an automated real-time inventory, providing up to 100% traceability* for up to 400 RFID tools**.

The XL smart cabinet brings tool tracking into a new era, providing accurate and effective tracking of all tool movements. Once identified by their RFID badge, the user can easily access the cabinet to borrow or return one or more tools. When the doors are locked, an automated content inventory is conducted. Every tool movement is tracked and time-stamped (Who, What, When, Where). Our connected solutions effectively combat the risks associated with tool loss (FOD/EMF).

(*) under nominal environmental, marking and layout conditions

(**) depending on tool size and overall dimensions

Challenges

Managing tools is a major challenge in Aeronautics, from their inventory to the risks associated with FOD (Foreign Object Damage) or FME (Foreign Material Exclusion).

Each year, tools left behind or lost during assembly or maintenance activities account for 30% of civil incidents and constitute a significant breach of safety. Poorly organized tool tracking can lead to a significant loss of productivity; activities such as borrowing and returning tools, or monitoring maintenance and calibration dates, are time-consuming and costly.

Smart foam (optional): To ensure detection of small metal tools that cannot be RFID-tagged (up to 80 tools per smart foam and 1 smart foam per cupboard)

* under nominal environmental, marking and layout conditions / depending on tool size and overall dimensions

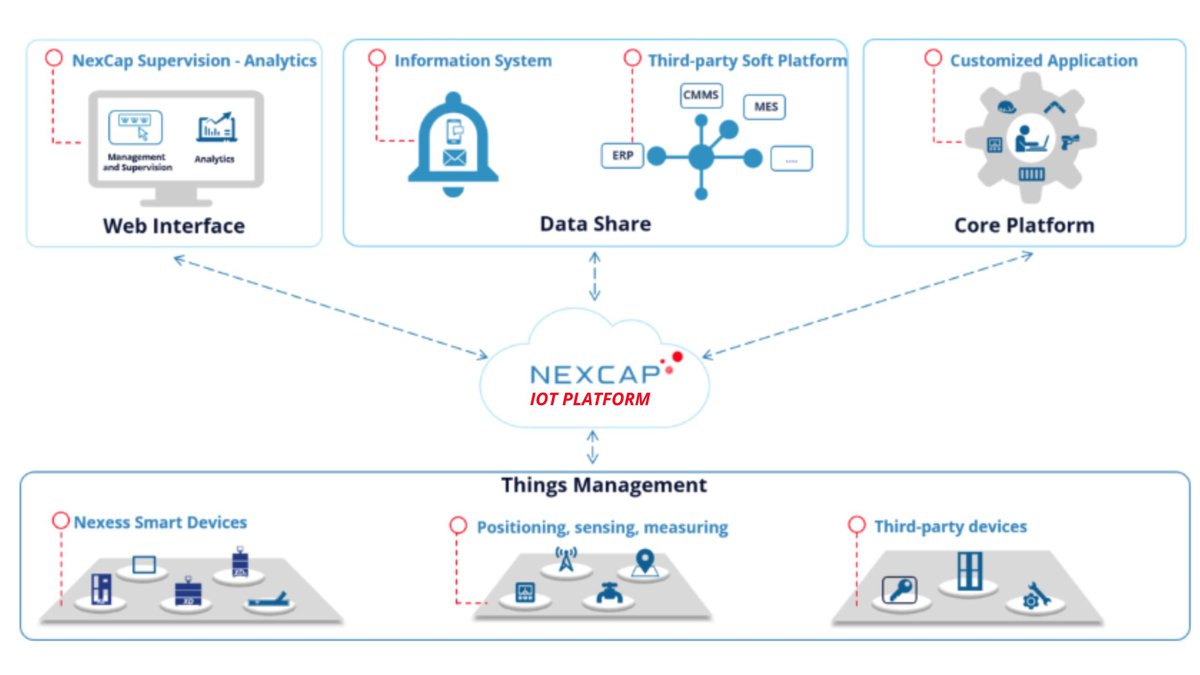

Things management, pour connecter facilement tous les objets :

Interface WEB